CAD360 The Best Conveyor Design Software

1. Locate overhead conveyor path. Keep parallel conveyor paths as close as possible to simplify installation. 2. Locate equipment, workstations, aisles, columns, walls, load and unload areas, etc. 3. Make a material flow diagram indicating the quantity of material to be handled per minute or hour. 4.

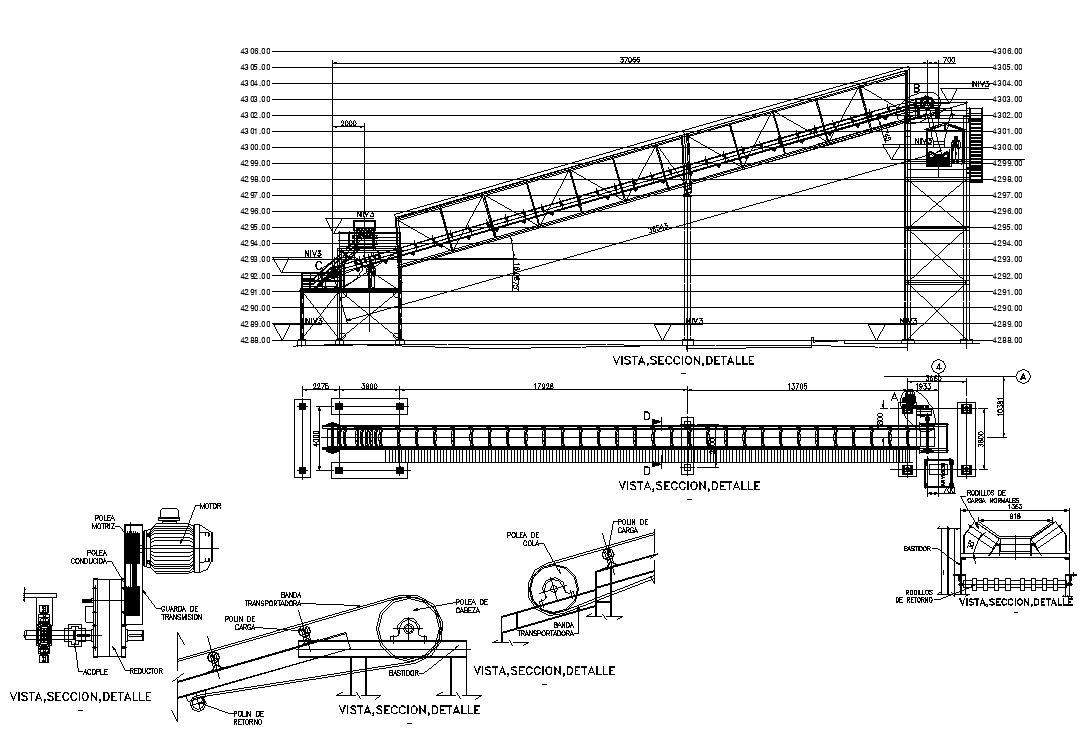

Belt Conveyor KCB138 Conveyor SectionsConveyor Sections

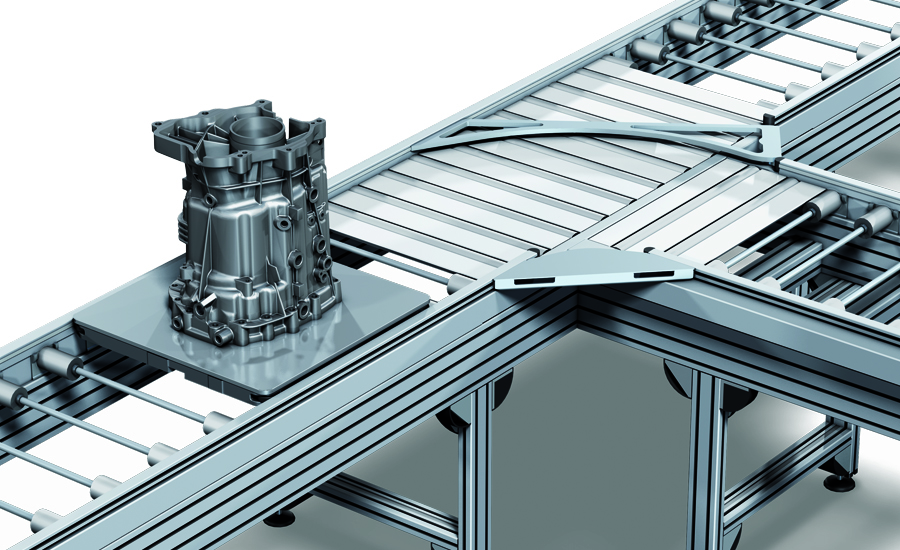

Conveyors are material handling systems that allow for easy transporting of products, from powder to bulk to complicated geometries. They are integral to all kinds of systems, as they provide a fast and safe method of handling large volumes of materials.

How to Choose the Right Conveyor System for Your Assembly Operation 20200420 ASSEMBLY

The Benefits of Our Conveyor Design Services. By leveraging Conger's transport conveyor system design and implementation services, you can: Cut costs, improve margins, and boost productivity by synchronizing, coordinating, pairing, and automating even your most complex components, systems, and technologies; Maximize productivity and reduce downtime with reliable mechanical and software.

Conveyor belt systems for Manufacturing NGS Engineering

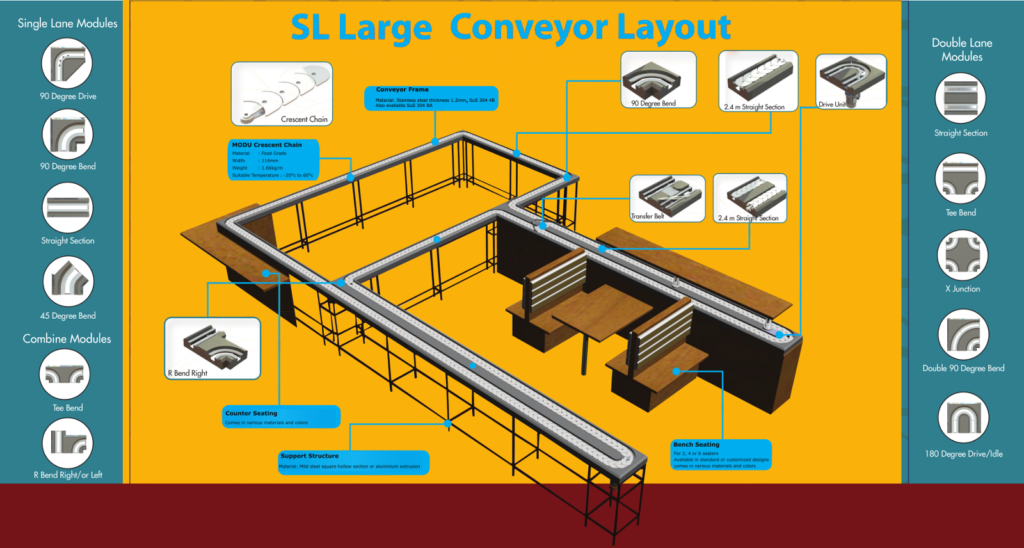

Design Guide The Design Guide provides technical details and spec drawings to help you start a conveyor system design or learn about your existing system. View .PDF Layout Guide Our Layout Guide is an additional tool that can be used in conjunction with the Design Guide in helping plan your conveyor system layout. View .PDF

Conveyor belt detail CAD machinery 2d view layout dwg file Cadbull

In simple terms, a conveyor system is a piece of equipment designed to efficiently move goods, ingredients or materials from one location to another. An intelligently designed conveyor system can improve production outputs, reduce the need for manual handling, increase factory space and even lower operational costs.

Designing a Conveyor System

For the average short-centre horizontal conveyor belt, under 300-foot centers, a 4-ply, 28-oz. duck belt may be safely used up to and including 20″ widths; 5- ply, 28-ounce duck for 24″ and 30″ belt widths; 6- ply, 28-ounce duck for 36″, 42″, and 48″ belt widths.

NEXUS Engineering Corp. Your exclusive designer of spiral conveyor. Conveyor, Conveyor system

System Design Services & Process. We use the latest design tools such as AutoCAD, Solidworks, and Navisworks to develop our designs quickly and efficiently helping you get your system up and running sooner. We also develop designs in 3D to help identify interaction points, clearances, and obstructions before your conveyor shows up to your site.

Roller Conveyors Science Channel How It's Made Discovery Science

Taking advantage of 3D design. CAD Schroer's solutions automatically convert 2D conveyor layouts into 3D models, which can then be further optimised using 3D collision detection. Any number of additional drawings can then be automatically generated from the 3D model, ready for dimensioning and annotation. The user can also conduct virtual.

Conveyor Layouts 888 Brands

Get Conveyor Design Layouts from Span Tech. Whether you need specialty conveyor systems or spare parts, Span Tech is here to help with innovative design layouts. Since our founding in 1988, we've made it our mission to exceed expectations and satisfy our customers. If you have a special application for your product, our team will provide a.

The Ultimate Guide to Conveyor Systems CiscoEagle

Tubular Drag Conveyor Layouts and Designs. Tubular drag conveyors by Chain-Vey are completely configurable to your existing setup. Configurations can include multiple inlets and discharges, optimized puck design, and many other options to make sure it's the right conveyor for you. Ability to convey both horizontally and vertically in a single.

Conveyors Archives Robot Units

A Mathematical Model to Optimize Transport Cost and Inventory Level in a Single Level Logistic Network Chapter © 2015 1 Introduction Due to increasing consumer expectations, services such as same-day delivery (SDD) have become one of the fastest-rising logistics components in the e-commerce industry.

What Is A Conveyor System? Applications, Uses, And Types Explained

Simple to design and operate; suitable for cartons, boxes, or totes that need to move a long distance. Sortation Conveyors Sortation conveyors are widely used in picking, packing, manufacturing, receiving, and shipping. They can send boxes, cartons, parts, or assemblies in different directions.

Belt Conveyors Light & Heavy Duty Conveyors

Conveyor Systems are mechanical devices or assemblies that transport material with minimal effort. While there are many different kinds of conveyor systems, they usually consist of a frame that supports either rollers, wheels, or a belt, upon which materials move from one place to another. They may be powered by a motor, by gravity, or manually.

Belt conveyors manufacturer India Conveyors, Mechanical design, Conveyor

A conveyor system is a mechanical device that moves materials from one place to another. These are common in the material handling and packaging industries for moving bulky or heavy items. They can minimize human error, lower workplace risks, and reduce labor costs. Working of a Conveyor System Conveyor systems are part of production processes.

Conveyor system plan detail Cadbull

Conveyor Length and Layout. The number of drives, pulleys, supports, and the type of conveyor system needed is dependent on the conveyor's length, routing, and elevation changes. These factors are crucial in determining the conveyor's overall design, which will directly affect its functionality and efficiency.

Conveyor designers can "build" the entire floor layout using my Conveyor Interface.

The first step in designing a conveyor system is to define your goals and objectives. What are you trying to achieve with your conveyor system? How will it fit into your overall production.